2021: Development of a low-stress grading device for sorting of live shrimps - Shrimp Grading

NEW GRADING DEVICE WITH NOVEL STRUCTURES INCREASES SELF- GRADING SUCCESS OF WHITELEG SHRIMPS L. vannamei IN AQUACULTURE CULTIVATION SYSTEMS

Mirko Bögner*, Amirhossein Karamyar, Christian W.G. Detsch, Matthew J. Slater

The Whiteleg shrimp, Litopenaeus vannamei, is the most widely produced shrimp species worldwide. This species has exhibited persistent increases in global production over the past decade. One of the most marked production problems with this shrimp species is the uneven growth among individuals, which can lead to higher cannibalism, imprecise feeding and uneven product size.

This can be prevented by size-grading the animals, but present methods are very invasive and can be stressful and harmful to the shrimp, as individuals may be injured or even jump out of the rearing tank. As the negative implications and disadvantages can be very high, live grading is seldom carried out by producers.

The Goal of the Grade aid project is the development of an animal friendly grading device for live shrimp to improve animal welfare and growth performance.

Introduction

Uneven growth of aquacultured shrimp leads to an increase in cannibalism, untargeted feeding and uneven product size. Size grading can prevent these effects. However, current sorting methods are highly invasive and cause high stress levels and flight responses. The animals can injure themselves and may even jump out of the tank.

In this study, a size grading device was developed that allows the animals to sort themselves voluntarily according to size in the cultivation tank. For this purpose, innovative structures were developed that are specifically adapted to the body shape and behaviour of the animals.

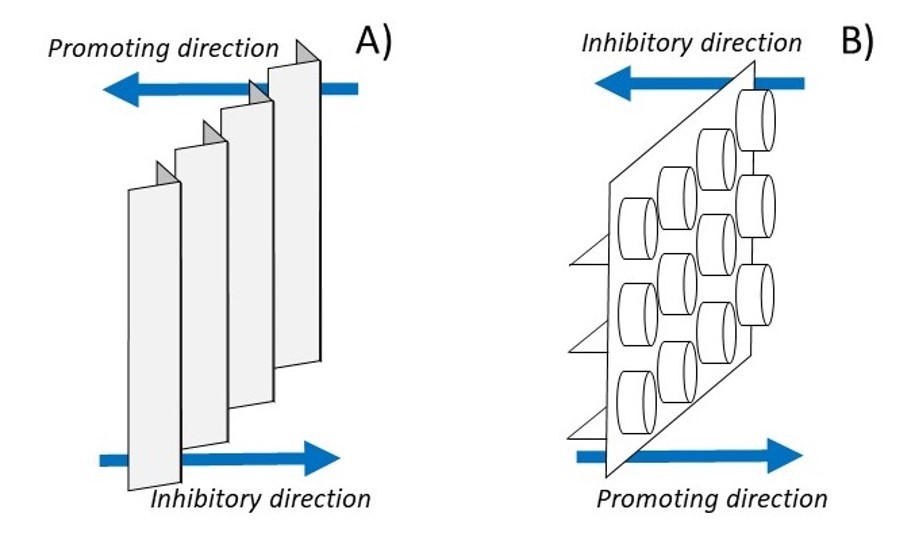

Figure 1: Design and mode of operation of the tested sorting elements.

A) Vertical V- shaped device, B) Device with tubes and horizontal bars.

These structures are conceptualised to either encourage or discourage passing of the grading device. Results demonstrate strong grading effects (75 %) on the distribution of shrimps between different tank compartments and the ability to separate shrimps of different size voluntarily (up to 85%). Small animals can be separated from the cohort without stress or any personnel effort and uniform size distribution of the shrimps can be guaranteed.

This voluntary grading system is expected to increase animal welfare and growth performance in shrimp farms while it reduces labour.

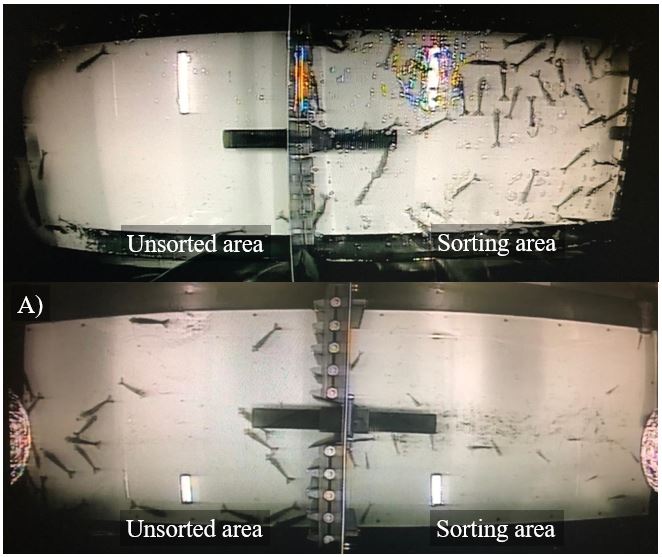

Figure 2: Distribution of shrimp after 36 h voluntary self- grading using tubular structures.

Materials and Methods

In the first experiments sorting elements (through which shrimp could pass) with different structures (tubes, wedges, bars, V- shaped) (Fig.1) were installed in the middle of the experimental tanks (2.5 x 0.7 x 0.7 m) (N=3). The control group had a perforated sorting plate as a subdivision (N=3). Twenty-five shrimp (18.4 g ± 2.9) were placed on each side of the tank and shrimp were of a size theoretically capable of passing the structures and perforated plates in both directions. The structures facilitate or make it harder to pass the device in one direction and thus divide the tank into a “sorting” and “non sorting” area. For each structure the distribution of the shrimps was documented hourly for 36 h. The most effective structure was used in subsequent experiment. In this experiment, twenty-five small (2.6 g ± 0.6) and twenty-five large shrimp (14.6 g ± 2.9) were placed in the “unsorted” area of the tank. The structures were narrowed so that only the small animals could cross it into the “sorting” area. Shrimps in both tank areas were counted hourly for 72 h.

Figure 3: Animals of different sizes after 72 h voluntary size grading with a device with vertical V- shaped structures.

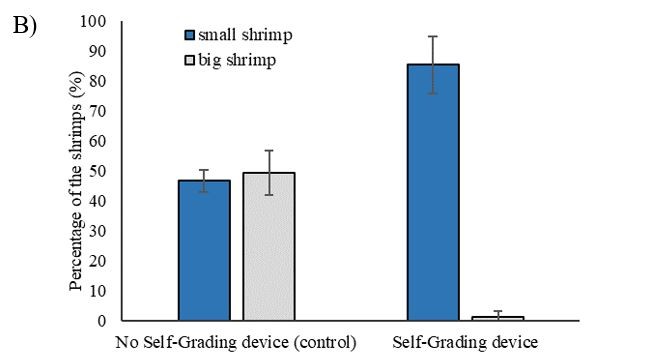

A) View of the „sorted“ and „unsorted“ area. B) Proportion of large and small shrimp in the “sorting” area after 72 h using grading structure and compared to control.

Results and Conclusion

In the first experiments, tubular structures resulted in 73% of animals moved into the sorting area. The use of wedges (59%) and bars (57%) had little supporting effect. The combination of wedges and tubes caused 75% movement to the sorting area as did the V-shaped structure (Fig. 2). In the second experiment with mixed size groups, the V-shaped structure caused about 85% of the small individuals to migrate into the sorting area (Fig. 3).

Tested devices with novel structures are effective and achieve high levels of self grading in shrimp!

Alfred Wegener Institute Helmholtz Center for Polar- and Marine Research

Am Handelshafen 12, 27570 Bremerhaven, Germany.

Email: Mirko.Boegner@awi.de

The Work in this project was supported by The AWI Innovation Fund.